Weaving mills are slowing in Caudry, a northern French town whose workers have been spinning fine lace for Chanel, Valentino, Dior and their high-fashion predecessors since 1825.

"I'm worried," said Laurent Sautiere, a 35-year-old worker with lacemaker Solstiss as he knelt before a clattering 10-ton Leavers lacemaking machine, cranking a steel wheel to halt the spinning. "There's less and less work."

Caudry is home to 10 lacemakers, including two of the world's biggest weavers for haute couture.

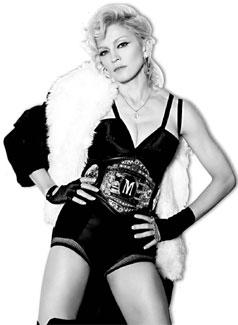

Together with nearby Calais, the town has 80 percent of the 100 million-euro ($139 million) global market for luxury lace. The factories' fabric adorned Hillary Clinton's gown at the 1993 presidential inauguration and dresses worn by Nicole Kidman and Madonna (right).

Production cuts

As the recession bites, the lacemakers, who've dominated the market with their Leavers machines, are scaling back production for the first time in three decades and cutting jobs. They risk losing further ground as Asian manufacturers acquire the machines and master the savoir faire.

About 13 percent of the 800 lacemaking jobs in Caudry, a town of 14,000 people, disappeared in 2008 and more will go this year, said Edith Mery, head of an organization representing French Leavers lacemakers. Noyon, a Calais lacemaker, filed for bankruptcy in November and plans to cut a third of its 438 jobs.

The worldwide luxury goods market faces its first recession in six years in 2009, an October study by Bain & Co said.

Calais and Caudry became lace centers in the 19th century, when Leavers machines were smuggled into France from Britain. The lacemakers survived two World Wars, Pope John XXIII's abolition of mantillas in churches in the 1960s, the fashion of unadorned dresses inspired by pop art in the 1970s, and imports of cheaper lace from China and Thailand.

While demand has shrunk, companies such as Dior say they will still turn to French suppliers.

"We continue to buy only French lace because its quality is the best," said Chloe Bourgignon, an assistant to lingerie designers at Dior in Paris.

That's little comfort to Sophie Hallette, Caudry's biggest lacemaker, which will report a loss for 2008 and this year, Chairman Bruno Lescroart said.

Solstiss, which unites four Caudry lacemaking families, may break even this year after a 30 percent revenue drop in 2008, said Herve Protais, its sales director. The two combined have a more than 50 percent share of the fine-lace market.

Survival

Solstiss charges about 30 euros a sq m for its best-selling, off-the-shelf 447-200 lace, called "volute", which featured on translucent Dior gowns this winter.

Prices go up to 3,000 euros a sq m when designers want something new created. As demand falls, prices are sliding, Protais said.

"My plan for 2009? Survive," said Christophe Machu, Solstiss' president, watching a worker insert 300 nylon threads into coils at his grandfather's plant in Bethencourt, on the outskirts of Caudry.

"Eighty-five percent of my cost is labor. I will be forced to adjust."

Caudry, where lacemakers are the biggest employers in the town, is seeking government help for the first time.

"This industry is part of the national heritage," Guy Bricout, its mayor said. "The state could help a little."

The Industry Ministry said it has no plan to support lacemakers.

Mery said the failure of even one manufacturer would be "devastating".

"The machines could be acquired by a foreign competitor," she said. "Skilled labor, key to the handling of the machines, may be lost for good."

The lacemakers work with designers including Alexander McQueen and Jean-Paul Gaultier on creations. For the past three decades, the strategy supported exports of 80 percent of production.

Lacemakers in high-volume segments like lingerie, including Noyon, have been hit by competition from Asia, Mery said.

That risk may spread to the luxury ready-to-wear industry as low-cost countries acquire more of the limited supply of Leavers and as Asian workers master the machines, she said.

In 1984, equipment makers stopped manufacturing Leavers, whose mechanism was invented in 1804 by British engineer John Heathcoat and still make the world's finest lace.

About 700 of the machines are in service, 80 percent of them in Caudry and Calais. French lace families systematically buy Leavers machines that go up for sale, keeping their competitive advantage at home.

Aging workers

Foreign competitors such as Hyogo, Japan-based Sakae Lace Co have acquired some.

"Sakae is upgrading its collection and is now making beautiful things," Mery said.

The possible liquidation of Noyon and the sale of its 60 Leavers machines are worrying because local lace families may not be able to buy all of them, Mery said.

Meanwhile, workers like Sautiere, who has been with Solstiss for 14 years, worry they may be let go.

"Already five workers have been laid off," he said, sliding fingers blackened by carbon dust over white spirals on his machine.

"And from what I know, the beginning of the year doesn't look good."