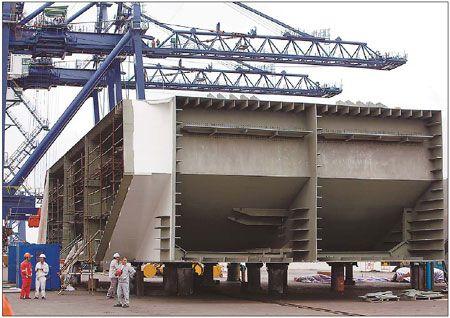

A section of the San Francisco-Oakland Bay Bridge made by Shanghai Zhenhua Heavy Industry Co Ltd (ZPMC) being loaded onto a ship in Shanghai on Monday. Kevin Lee / Bloomberg

A section of the San Francisco-Oakland Bay Bridge made by Shanghai Zhenhua Heavy Industry Co Ltd (ZPMC) being loaded onto a ship in Shanghai on Monday. Kevin Lee / Bloomberg"Made in China" used to be synonymous with cheap consumer goods, but one machinery maker wants to change the image of the nation's manufacturing sector by taking part in the world's most challenging infrastructure projects.

On Monday, China's Shanghai Zhenhua Heavy Industry Co Ltd (ZPMC), formerly known as Shanghai Zhenhua Port Machinery Co, finished the final four pieces of fabricated steel for the San Francisco-Oakland Bay Bridge.

In 2006, the company beat strong rivals from Japan, South Korea and Western Europe to win the bid for the Bay Bridge project, due to be open for traffic in 2013.

The 50,000 tons of steel, with a contract value exceeding $350 million, are part of the $7.2 billion Bay Bridge project.

The project includes reconstruction of the eastern span, which was damaged in a 1989 earthquake.

The new section will be able to resist quakes of up to magnitude 8 on the Richter scale.

The Bay Bridge project has a global profile "and it is also a milestone for Zhenhua in entering the world's major bridge construction" sector, Kang Xuezeng, president of ZPMC, said during the steel fabrication completion ceremony on Monday.

"I am here to announce that we are qualified and confident of constructing more sophisticated steel bridges and building our presence in the world market," Kang said.

ZPMC, founded in 1992, now accounts for 75 percent of the global port equipment production market.

The construction company is entering the bridge sector and "I expect many more great things" from the company, said Steve Heminger, executive director of the San Francisco Bay area's metropolitan transportation commission.

"It is time to be confident, but not yet to be proud," said Xiang Haifan, a professor at Tongji University, who is also a member of the Chinese Academy of Engineering.

According to Xiang, ZPMC's chief competitive advantage over international rivals is cost.

A Japanese company wanted more than $600 million to undertake the project, while a South Korean company quoted more than $400 million.

"Our cost was about half that of Japan's, which makes Zhenhua outstanding with its high quality," Xiang said, adding that China's bridge construction abilities still lag behind those of Japan or South Korea, but the gap is likely to vanish in the next 10 to 20 years.

"Although the Bay Bridge project didn't bring Zhenhua substantial profit, it brought many large international contracts and gave the company fame in the global bridge sector," said Wang Hexu, an industrial analyst from Huachuang Securities Brokerage Co Ltd.

Since 1998, ZPMC has undertaken several major steel bridge projects in China and abroad, including the Shanghai Donghai Bridge and the Golden Ears Bridge in Vancouver, Canada.

Since it already dominates global port equipment production, ZPMC is finding it increasingly hard to expand in this sector, so it has decided to explore related industries.

"Steel fabrication has become our next goal. Through providing steel decks, we have driven into the world's high-end bridge construction market," said Huang Hongyu, vice-president of ZPMC.

"Currently, steel fabrication and marine engineering account for more than 40 percent of Zhenhua's total revenue, and by the end of 2015, the proportion will reach as much as 50 percent," said Kang.

Source:China Daily

Weekly review