If China is granted patents for the CRH380A train in the US, it will help CSR take part in US high-speed railway projects, industry insiders have said.

CSR Corporation Limited, one of China's two manufacturers of high-speed trains, is mulling over whether to apply for patents for its CRH380A train in the United States, a senior company technician said.

Ma Yunshuang, deputy general manager and technology director of CSR Qingdao Sifang Co Ltd, which developed the CRH380A train, said that the company has hired US lawyers to assess its intellectual property rights for the train and compare them to existing patents in the US.

"The result of their initial assessment came out good, which means China can apply for patents (for the train) in the US. We are now planning on this," he told China Daily, without giving more details.

However, whether the patents will be granted is not under the company's control, he added.

If China is granted patents for the CRH380A train in the US, it will help CSR take part in US high-speed railway projects, industry insiders have said.

Ma said the train's technologies are rooted in Japanese technologies, but the CRH380A train is no longer the train imported from Japan years ago and is safe to use on the Beijing-Shanghai high-speed railway, which will soon open.

Previous media reports said Japan's Kawasaki Heavy Industries transferred the technologies of a 200-km/h train to China in 2004. In the same year, China also bought technologies of 200-250 km/h trains from Bombardier and France's Alston.

CSR Qingdao Sifang Co Ltd partnered with Kawasaki Heavy Industries and produced the 200 km/h trains named CRH2 in China.

In the following year, China inked a deal with Siemens from Germany, which agreed to transfer technologies of a 300-km/h train and formed a partnership with Tangshan Railway Vehicle Co Ltd under China CNR Corporation Limited, the other major manufacturer.

There have long been voices, including Zhou Yimin, the railway ministry's former deputy chief engineer and science and technology department director, doubting the reliability of the CRH380A model.

Zhou was quoted by the 21st Century Business Herald as saying on Tuesday that "the foreign companies wrote clearly in the contracts that the top speed for operation should be 300 km/h, not 350 km/h".

He said although the manufacturing capabilities of the rail industry have improved a lot with the introduction of overseas prototypes in recent years, China's research and development remain peripheral.

A railways ministry spokesman dismissed the comments on Wednesday, saying Zhou retired in 1998, too early to know the current situation.

Ma agreed that the trains imported in 2004 are not suitable to run at 350 km/h or 300 km/h.

"But the current trains are not the imported ones," he said.

The CRH380A train, for instance, has made innovations on at least three key parts - bogie, train head and train hull.

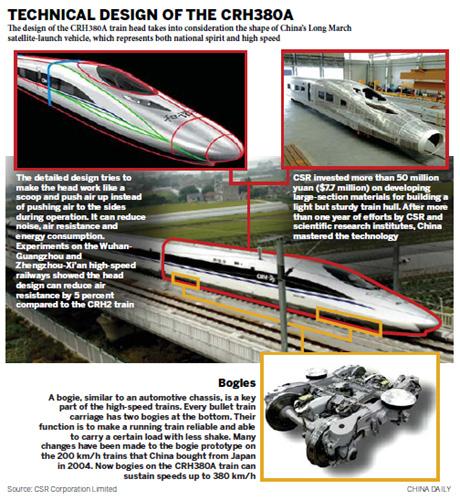

A bogie, similar to an automotive chassis, is a key part of high-speed trains. Every bullet train carriage has two bogies at the bottom. Its function is to make a running train reliable and able to carry a certain load with less shaking.

"If you compare a train to a running man, bogies function to make sure the runner doesn't fall, doesn't suffer muscle strains and doesn't feel dizzy," he said.

Changes to the bogie prototype are necessary because China's railways are different from Japan's.

For example, China's trains run on ballastless tracks, but in Japan, trains run on ballast tracks. China's railway tunnels have a cross section of 100 square meters, but in Japan the railway tunnels have a cross section of 64 square meters.

These differences have an impact on train operations, and China could not just use the imported train as it was, he said.

In addition, CSR later started to develop 300 km/h trains and 380 km/h trains, but the bogie technology Japan transferred to China is for 200-250 km/h trains and cannot sustain the higher speed.

An attendant displays the use of rotating chairs in the business class carriage of the high-speed bullet train on June 16. [Xinhua]

Ma's team made adjustments to the bogie prototype to make trains able to run smoothly at 380 km/h, based on data gained from months of experiments on the high-speed railways.

"If you compare the bogie prototype imported from Japan with the current bogie used on the CRH380A, you will find they are different," he said.

"Our technologies may originate from foreign countries, but it doesn't mean that what we have now all belongs to them. We have added our knowledge gained from experiments to the train and made designs to satisfy our needs, so the new train is not theirs anymore."

In addition to bogies, the company also redesigned the train head so that air resistance of a CRH380A train is 5 percent less than for a CRH2.

Meanwhile, after more than one year of work accompanied by failures, China mastered the technology of manufacturing large-section materials for building a light but sturdy train hull, which Japan refused to transfer but wanted to supply for bigger profits.

Ma said these efforts embody the strategy of initial assimilation followed by innovation.

"A simple technology import is using the technology as it is, but we did much more than that," he said.

"After the technology transfer was made, we did analysis and experiments on every part, trying to understand its design concept and the form of the technology used and figure out what we should do to make it work as we want."

According to Ma's estimation, more than 100 million yuan ($15 million) has been poured into experiments and innovations of new high-speed train models, an amount 10 times what the company spent on the development of a train model in the past.

He Huawu, chief engineer with the Ministry of Railways, told China Daily that China's high-speed rail has acquired nearly 2,000 patents at home.

Ma admitted that some parts of the new train, such as bearings, are made by Japan because of the country's limited industrial capability.

But all the parts bought from foreign countries are tailor-made according to CSR's technical requirements, which makes a difference, he said.

In CSR's development of 300-350 km/h trains and later 380 km/h trains, the Japanese side cooperated with CSR as a supplier, he said.