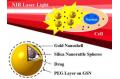

Swiss and Chinese scientists have developed a new way of making the porous TiO2 electrode for solid state dye-sensitized solar cells (ss-DSSCs). The method could be more compatible with large scale manufacturing processes.

The team from the Federal Polytechnic School in Lausanne and the Changchun Institute of Applied Chemistry were trying to come up with an alternative to the titanium dioxide nanoparticle paste that has been used to make electrodes for DSSCs in various forms since their discovery by Michael Gr tzel and Brian O Regan in 1991.

There are several problems with nanoparticle-based electrodes, explains project leader Nicolas T treault, who spoke to Chemistry World during the recent Materials Research Society meeting in Boston, US. They are relatively poor electron conductors, he says, which isn t such a problem in cells with liquid electrolytes. But because these liquids tend to leak over time and are less suitable for mass production, there has been a move towards solid 'hole transport material' replacements.

However, this throws up problems of its own. Since electrons are not transported through the structure quickly enough, they tend to recombine with positively charged holes in the hole transport material rather than making their way out of the electrode to generate an electrical current. So we need to speed up the electrons in the TiO2, says T treault.

To do this the team designed a new process using rod-shaped particles, which self assemble and join together into nanowires in 15 seconds from aqueous solution. We found that when the nanorods fuse together their crystal structures are aligned which helps fast transport, says T treault.

Henry Snaith, who researches DSSCs at the University of Oxford, UK, agrees that improving charge transport should help improve the performance of the cells.

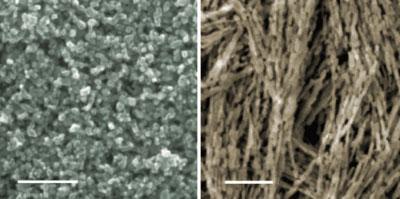

The nanowire electrode (right) transports electrons much faster than the nanoparticle equivalent (left) and has larger pores which are more easily filled with the hole transport material (Image by Nicolas T treault)

Not having to burn out a polymer binder [as is required for the nanoparticle paste] opens up a few more possibilities in processing, Snaith adds. However, he points out that the method still requires heating and treatment with titanium tetrachloride - in the same way the nanoparticle structures would - to get good conductivity between the individual wires. T treault acknowledges that this is a drawback, but hints that the team is working on a way to eliminate the heating step, which would open up the process to polymer backing materials to make flexible ss-DSSCs.

Snaith notes that the nanowire structure is more porous than the particle-based electrodes, which should make it easier for the hole transport materials to penetrate and fill the pores effectively. Better pore filling means the light-harvesting dye on the electrode surface shouldn't degrade so easily. However, he points out that to get a significant increase in power generation from ss-DSSCs will probably require a combination of more radical changes to the cell design.

(Source: Chemistry World)

Related News

Photos

More>>trade

market

- Ma Wen Spoke at the National Videophone Conference on the Special Task of

- The Second Joint Conference of Corruption Prevention: Adhering to the guidance

- Conclusion Ceremony of the Workshop on Corruption Prevention of Asian and

- He Yong Stressed at the National Experience Exchange Conference of Deepening

- He Guoqiang Stressed at the First Session of the Joint Conference of Corruption

finance

- NBPC Office Holds a Special Lecture on UN Convention Against Corruption and its

- National Experience-Sharing Conference on Deepening Government Affairs Publicity

- The Second Conference of States Parties to the United Nations Convention against

- Representatives of the Workshop of Corruption Prevention for Asian and African

- The Workshop of Corruption Prevention for Asian and African Countries Came Back