By: Shuaigang

Galvanizing-line inspection staff of ThyssenKrupp AG completed the two-week examination work on equipment of EKS Project, which was contracted by MCC-SFRE Heavy lndustry & Equipment Co., Ltd. (MCC-SFRE), on July 8, 2009. As a result, ThyssenKrupp AG staff put a premium on the product quality, package quality, equipment for quality inspectors as well as the task performance of SMS s employees.

The overall quality inspection was commenced on June 22, 2009, which was undertaken by galvanizing-line quality supervisor of ThyssenKrupp AG and equipment-maintenance project manager of ANSC-TKS Galvanizing Co. During the two weeks, detailed inspection were executed on the four galvanizing lines processed by MCC-SFRE, especially on the quality of processing, assembly and package of the equipment.

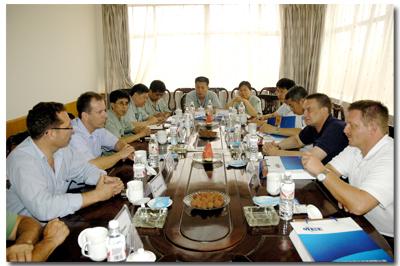

After the inspection, the representative of ThyssenKrupp AG submitted a written report on the examination results and signed the Minutes of Talks. According to the documents, the four TKS lines were fully in compliance with the requirements. The Germany partner gave a full recognition on the quality of TKS Project. They expressed their admiration on the professional ethics held by the quality inspection staff of MCC-SFRE, and expected to cooperate with MCC-SFRE on a wider and deeper basis.